In the printing industry, solvent consumption is a critical issue—especially for solvent-based inkjet printers. As the most widely used type of ink, solvent-based inks are essential in advertising, signage production, and packaging printing. However, their high volatile organic compound (VOC) emissions pose serious environmental challenges and increase operational costs.

Solvent usage depends on multiple factors, including ink formulation, printing technology, equipment design, environmental control, and regulations. Among these, the ink pump—the “heart” of the printer—plays a decisive role by delivering ink from the storage container to the printhead, ensuring smooth and stable operation.

• Precise flow control prevents over-supply and reduces solvent waste.

• Intelligent ink pumps dynamically adjust ink delivery according to print demands, optimizing solvent efficiency through variable pump speed.

• Continuous, stable supply systems minimize solvent evaporation from tubing and printheads.

• Solvent-based inks thicken during circulation due to evaporation.

• Pumps must work with viscosity sensors to automatically replenish solvents in precise amounts.

• Inaccurate or delayed pump response can lead to overcompensation—adding too much solvent and increasing consumption.

• Leaks = Hidden losses. Worn seals or loose fittings allow solvent to escape.

• Negative pressure control: Poor calibration may cause ink backflow or printhead drying, forcing extra cleaning cycles and raising solvent use.

• Efficient recovery ensures unused ink and solvent are recycled effectively.

• Filtration systems in the pump should remain unclogged to avoid higher system resistance and unnecessary energy use, which indirectly increases solvent consumption.

• Real-time adjustment: Modern printers leverage smart control systems to automatically balance ink supply with task load.

• Energy-saving modes: Reduce pump speed during standby to minimize solvent evaporation.

|

|

|

|

|

| ink pump TFSD | ink pump TF30B | ink pump TF22 | ink pump TF30A | ink pump MG |

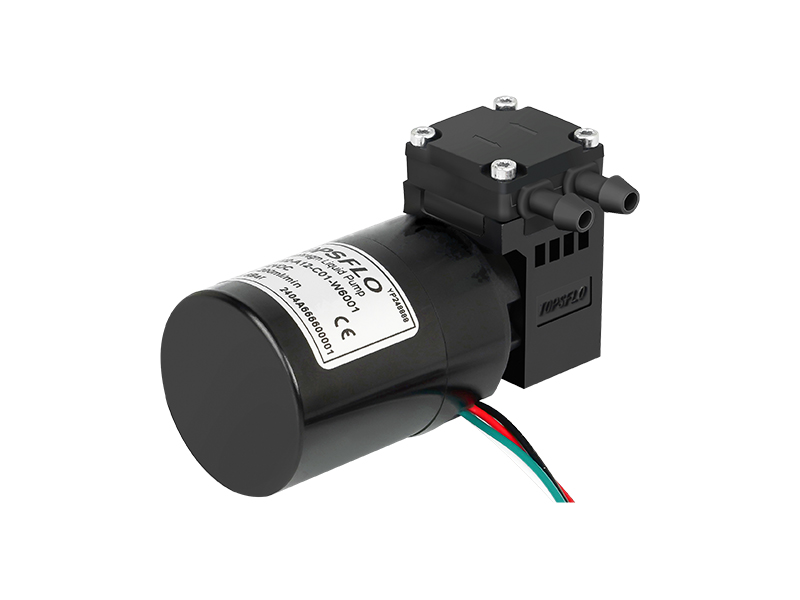

To meet the specialized demands of solvent-based inkjet printers, Topsflo ink pumps integrate advanced engineering and precision control to minimize solvent consumption while maintaining top-tier printing performance.

Key Advantages

♦ High-Precision Flow Control: Smooth, low-pulsation output prevents excess ink supply and solvent waste.

♦ Advanced Sealing Technology: Static sealing and enclosed diaphragm surfaces ensure zero leakage and minimal VOC evaporation.

♦ High-Performance Motor Design: Proprietary motors deliver durability, low maintenance, and consistent performance under demanding tasks.

♦ Environmental Compliance Support: Helps businesses reduce VOC emissions and enhance solvent recovery efficiency.

Choosing Topsflo Ink Pumps means more than efficiency—it’s a commitment to sustainability.

By maximizing solvent utilization and minimizing losses, businesses can:

• Improve print consistency

• Lower operational costs

• Achieve greener manufacturing goals

💧 Maximize the value of every drop of solvent — Topsflo, your professional partner for a brighter, more sustainable future!

Optimizing Solvent Consumption in Solvent-Based Inkjet Printers How Smart Ink Pumps Reduce VOCs, Improve Efficie…

Background Introduction Inkjet printers, which are used to spray ink droplets onto a printing medium to form words or i…