Brushless centrifugal pumps feature a simple and compact structure, small size, lightweight, and low noise. They offer high efficiency in applications with large flow rates and medium head, providing continuous and stable flow and head during operation, suitable for various conditions. They are commonly used to transfer large volumes of low-viscosity liquids such as water and chemical solutions.

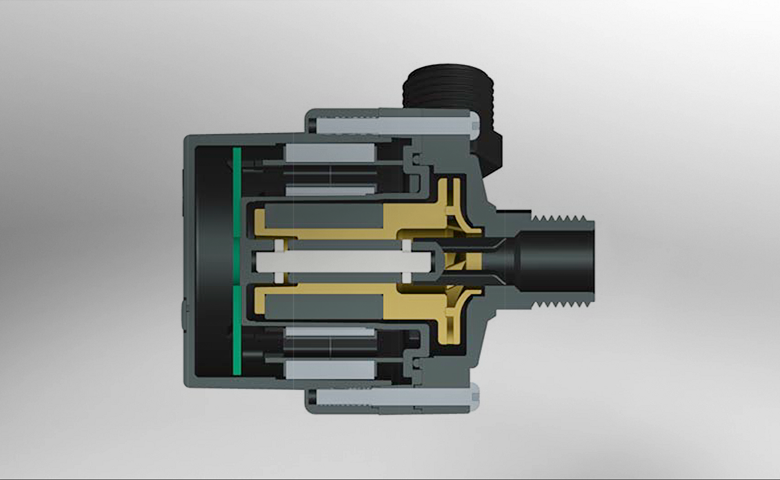

The static seal design isolates the liquid from the motor, preventing medium leakage. The stator and circuit board sections of the pump can be encapsulated with epoxy resin to ensure 100% waterproofing, enabling submersible use.

The rotor has a low dynamic balance rate, and TOPSFLO pumps operate with 5-10 dB(A) less noise than similarly performing brushed DC pumps, with noise levels as low as 22 dB(A).

Brushless DC pumps are more efficient than their brushed counterparts, achieving the same performance with lower power consumption.

The pump is driven by intelligent programming with soft-start to avoid sudden impacts and includes built-in protection features. If overloaded, the overcurrent protection on the circuit board is triggered to protect the motor and pump.

The brushless DC pump uses a permanent magnet motor, where the rotor drives the impeller without carbon brushes, eliminating commutation vibration. With FOC control, the commutation is smoother.

The working principle of a brushless centrifugal pump is to draw liquid into the center of the pump body, where centrifugal force generated by the rotating impeller pushes the liquid out into a pipe or container.

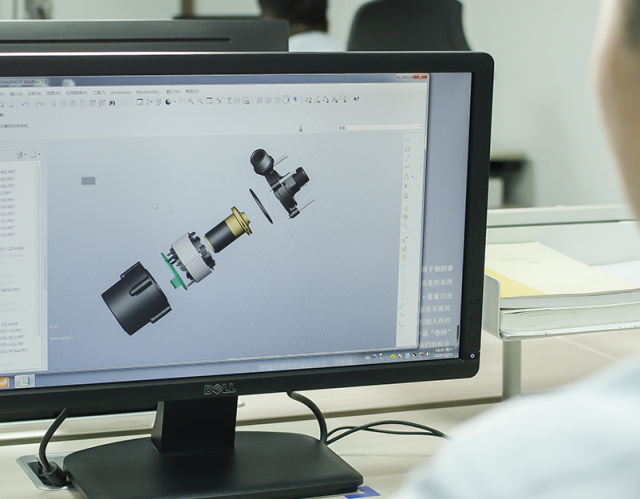

TOPSFLO has an independent R&D and technical service team, offering professional design that caters to personalized needs while providing standardized products. TOPSFLO can assist you make the right choice to give your product a competitive edge.

We can customize the size and performance parameters and offer different motor types and electronic components to meet diverse application requirements.